Development History

2014: Established the factory — 2018: Commenced production — 2018-2021: Explored deep processing and branding without success — 2021-2023: Focused on initial walnut processing, primarily using Xinjiang walnuts; found that labor-intensive processing was unsuitable for large-scale development. 2023-present: Focused on mechanized development of local walnuts in Shanxi

June 2023: First local walnut production line put into operation

September 2023: Shipped to the first European customer

November 2024: First European customer provided quality feedback and re-ordered

January 2025: Products distributed to domestic factories (including Hong Kong) and multiple international markets, including France, the UK, Germany, Spain, Turkey, etc.

April 2025: BRC certification upgraded from Class B to Class A.

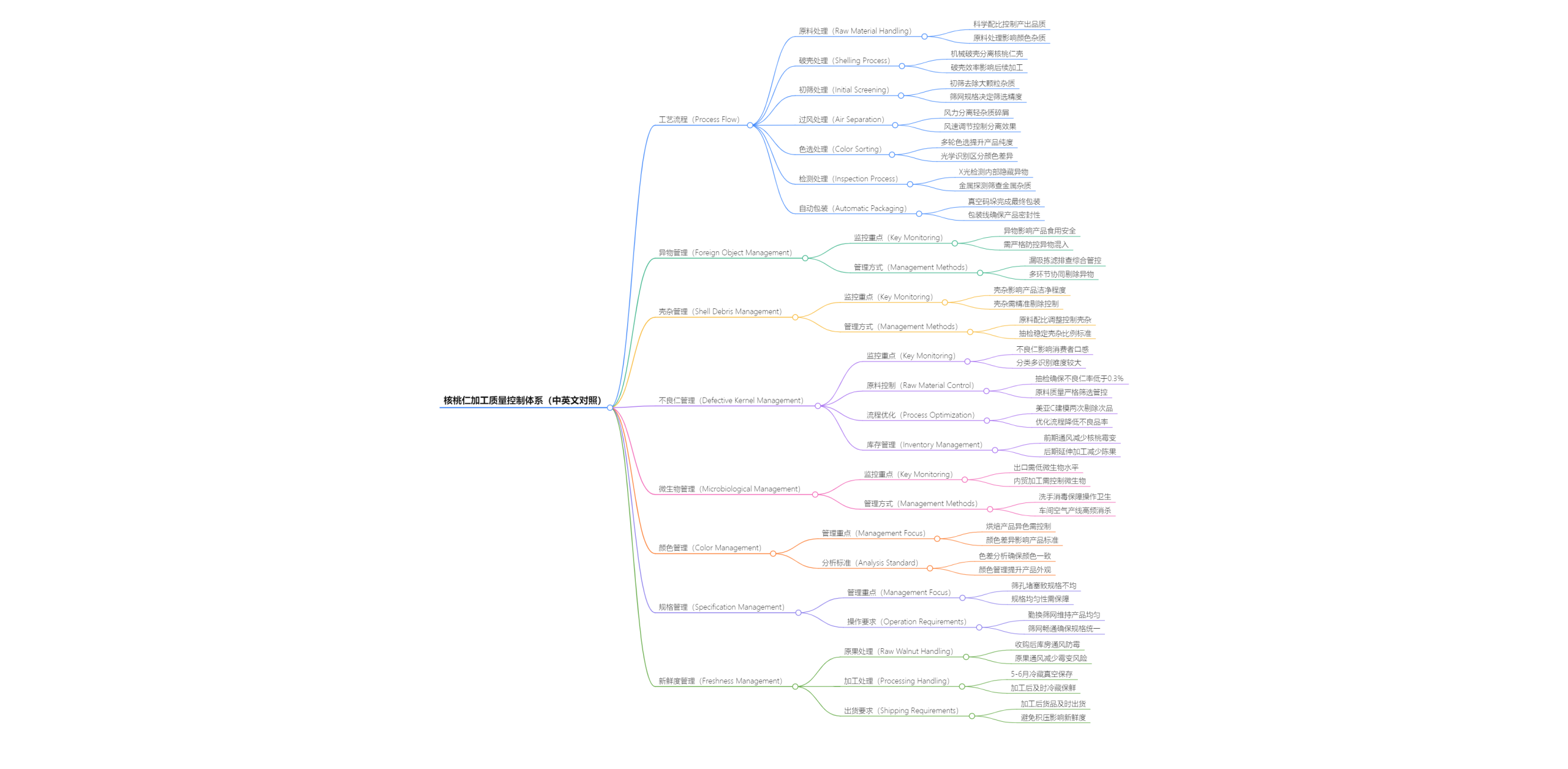

1、Walnut Kernel Production Processes and Quality Management

Raw Material Handling:

Control the quality of output (color and impurities) through scientific ratio of raw materials

Impurity Removal

Eliminate foreign objects and defective kernels from raw materials to ensure product quality

2、Foreign Object Management

One leakage check, one suction, one manual sorting, three filters, one comprehensive inspection

3、Shell Debris Management

One ratio adjustment, two sampling inspections, three stability controls

4、Defective Kernel Management

Raw Material Quality Control: Regularly sample raw materials and ingredients to ensure defective kernels account for <0.3%, with strict monitoring to guarantee product quality

Modeling and Process Optimization: Use the Meiya C modeling method, performing two rounds of elimination to reduce defective rates and improve efficiency

Inventory Management: 1. Increase ventilation in the early stage to reduce mold growth; 2. As processing scale expands, extend to green husk processing to reduce mixing of old fruits

5、Microbiological Management

Hand washing and disinfection + High-frequency workshop disinfection + Air disinfection + Production line disinfection + Experimental verification

6、Color Management

Control of Abnormal Colors in Baked Products and Standard Color Difference Analysis

7、Specification Management

Simple to manage; frequently replace screens to prevent blockages causing uneven specifications

Ensure screen mesh is unobstructed to maintain product uniformity

8、Freshness Management

(1)After purchasing raw walnuts, ventilate the warehouse for one month to prevent increased mold

(2)From May to June, processed walnut kernels are directly vacuum-sealed and stored in cold storage

(3)After processing, products are not stockpiled and are shipped promptly

Warehouse ventilation to prevent mold; raw walnuts are refrigerated after processing

9、Other Management

(1)Management of rejected materials: Rejected materials are not reprocessed into main products

(2)Product turnover management: Disinfection, covered containers, no contact with the ground to prevent foreign objects and microbial growth

(3)Management of dropped materials: Dropped materials are not reprocessed into main products